|

|

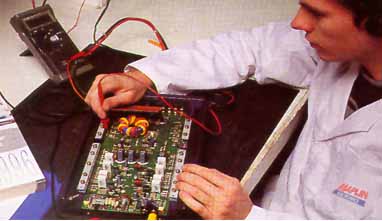

Our Technical Support line is open from 9 am to 5:30 pm Mon to Friday and Saturday 9:30am to 5pm. The number to ring is 0906 302 1353 and the calls will be charged at 50p per minute (BT Rate).All answered calls start with a brief message stating the nature of the service and any restrictions. We will endeavour to answer any question you have on any of our products. If an answer or information is not readily available then you will be asked to provide a telephone number. Once the information is obtained the engineer will call you back free of charge. You must obtain permission from your telephone account holder before using this service. It will save time if you have all relevant details to hand, e g catalogue page number for components, project book number for kits, and if replacement or additional parts are required, your customer number and post code. It is seldom that kit/project fault finding can successfully be carried out over the phone and can be very time consuming. We recommend you take advantage of our ‘get you working service’. The free ‘Do You Do?’ service on 0870 264 6005 (Standard National Rates apply) is open from 9 am to 5:30 pm Mon to Friday. If you know what you want but are not sure if we stock it then this is the service to ring. This line is not able to provide technical advice. If you write or e-mail, please keep technical enquiries separate from any other enquiry or order. Address your letter to the: Technical Department, Maplin Electronics, Valley Road, Wombwell, Barnsley, S Yorks, S73 0BS. Address your e-mail to technical@maplin.co.uk, or doyoudo@maplin.co.uk Please ensure that

your customer number / account number or a copy of the Maplin store receipt is provided. We will do

our utmost to answer your enquiry within 2 working days of our receiving it. We are unable to offer

the service on projects where the kit has been discontinued for over one year. We are unable to

help with the design of your equipment or the redesign of Maplin projects. We will however, assist

you to find the parts you need from our range of products. Enquiries about projects appearing in

magazines must refer to the relevant magazine issue number. |

|

Copyright ©1995-2002 Maplin Electronics Plc. All rights

reserved. |